MAINTENANCE

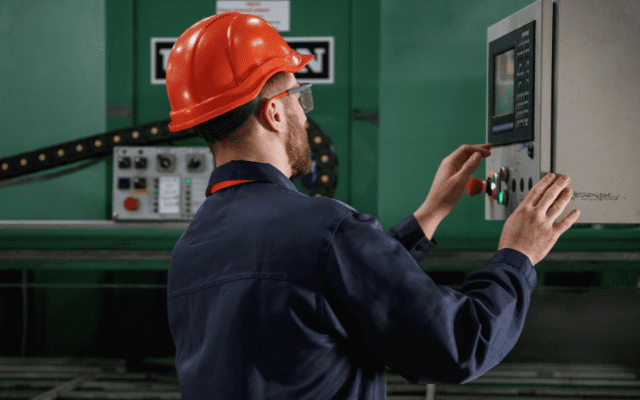

Maintenance and consulting services are designed to keep your operations running seamlessly and without disruption. Our comprehensive solutions cover everything from downtime reporting and root cause analysis to tool life, energy, and change management. By integrating intelligent diagnostics, real-time analytics, and predictive tools, we help you extend equipment life, reduce operational costs, and maintain consistent performance. Our systems not only fix problems, but they prevent them. Stay ahead of potential failures, streamline maintenance workflows, and ensure your manufacturing ecosystem remains agile, efficient, and future-ready.

Services

Optimize Production with Intelligence and Control

Down-Time Reporting

Track and report equipment downtime instantly for quicker diagnosis and recovery.

Root Cause Analysis

Pinpoint the exact cause of failures using structured analysis tools to prevent reoccurrence.

Tool Life Management

Track tool usage and predict replacements to avoid breakdowns and maintain precision.

Down-Time Analytics

Visualize downtime patterns and discover trends to reduce overall production loss.

Energy Management

Monitor and optimize energy consumption to reduce waste and lower operational costs.

Change Management (4M)

Manage changes across people, tools, materials, and processes to ensure smooth transitions.